Significance

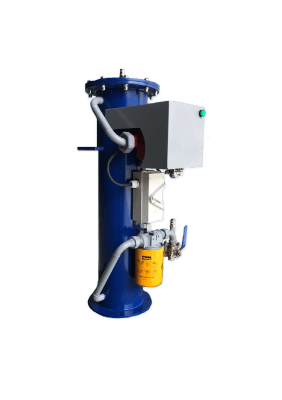

The purpose of the DryTrans unit is to dehydrate the paper insulation using the oil as a medium. When we dehydrate the oil, we are affecting the equilibrium of the moisture content between the oil and the paper with temperature and load as factors to consider. Once the oil has been dehydrated, a loss of equilibrium is created and forces moisture trapped in the paper to migrate to the oil. Once this occurs the oil is again filtered due to the permanent installation of the DryTrans unit and this process continues keeping the moisture levels at less than 10 PPM. ReadMore>> The technology of moisture adsorption is achieved through the use of molecular sieve beads that trap and retain water from the oil. The media allows for a slow and unobtrusive moisture management that is in sync with the migration of moisture between oil and paper. The unit draws in the oil from the transformer, through the use of the pump in our system, at which time it is subjected to the media and the moisture is removed. The oil is then passed through a micron filter which removes carbon and other contaminants after which the oil is returned back to the transformer. <<ReadLess

The DryTrans MMS90 units have been designed and built in accordance with the IEEE Standard C57.140-2006 – IEEE Guide for the Evaluation and Reconditioning of Liquid-Immersed Power Transformers, Section 7.2.

THE PROOF IS IN THE SLUDGE

In order to effectively remove moisture from oil, we use a material called ZEOLITES. Zeolites are essentially molecular sieve material in very small loose bead form. We use molecular sieve 3A for our DryTrans application. This media is a highly adsorbent material which has a high affinity for adsorbing water molecules. Over a period of time, the molecular sieve will get saturated at which time the media has to be replaced. However, the time to replacement is dependent on various factors and as a result, cannot be predicted easily. With the MMS90, we have incorporated the use of 2 moisture sensors (inlet and outlet) and this enables us to determine the difference between the two which will indicate the need for media replacement or not. ReadMore>> <<ReadLess

Our goal is to optimize the performance of the transformer, extend its life, protect the environment, and create a safe and efficient workplace.

DryTrans can help achieve this goal.

A Suite of Moisture Management systems for all rating transformers

TRAM Series

AMOUNT OF WATER REMOVAL

3-5 Liters

5-7 Liters

10-12 Liters

10-12 Liters

BENEFITS OF OIL FILTRATION

Reduces the moisture content in the oil

Enhances the Breakdown Voltage value

Reclamation or Regeneration with Degassing

Reduces maintenance and replacement costs

Reduces particles contamination

Reduces the risk of sludge build-up

AREAS OF APPLICATION

POWER UTILITIES

OIL & GAS

HEAVY INDUSTRIES

SOLAR PARKS

COMMERCIAL APPLICATIONS

MILITARY & DEFENSE

PROCESS INDUSTRIES

PLANTS

DryTrans is a brand of moisture management systems under the AVACO banner. It is a result of two decades of industry experience. AVACO Solutions is based out of SHARJAH, U.A.E. DryTrans is designed and manufactured in the United Arab Emirates.

Downloads

06-573-8439

+971 6-573 8597

Contact Address

Sharjah Airport Free Zone SAIF Zone Q3 – 190 P.O.Box: 514585 Sharjah, United Arab Emirates

support@drytrans.com