Why is Moisture The Enemy?

Transformers are one of the most important capital assets that a Utility can own. Maintaining a healthy transformer is a core practice of any maintenance program. There are many variables that affect the life expectancy of the transformer. The most important of all being the moisture content in the solid and the liquid insulation. Moisture in the transformer is the enemy and its presence is directly related to the dielectric strength of the oil and paper. ReadMore>> <<ReadLess

At DryTrans, we believe in a healthy, reliable and well-maintained network. The goal is to optimize the performance of transformers, extend life, protect the environment, and create a safe and efficient workplace.

Understanding Moisture

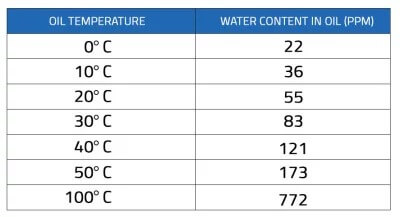

Moisture in oil is measured in parts per million (ppm) using the weight of moisture divided by the weight of oil. Water can be present in oil in a dissolved form, as tiny droplets mixed with the oil (emulsion), or in a free state at the bottom of the tank holding the oil. Demulsification occurs when the tiny droplets unite to form larger drops which sink to the bottom and form free water. When the moisture in oil exceeds the saturation value, there will also be free water precipitated from the oil in suspension or drops. In general, the moisture content in the oil lowers the insulating system dielectric strength and allows flashover that can damage a transformer. Moisture can also accelerate paper-insulation aging rates that will reduce the expected useful life of the equipment for mineral oil, a generally accepted maximum moisture content is 30 ppm.

Moisture Testing

• Online Oil Filtration system (ONLINE)

• Karl Fisher Titration ASTM D1533 Method (OFFLINE)

• Scheduled maintenance Oil change (OFFLINE)

Effects of Moisture

Most of the water produced during aging remains in the windings, reducing the insulation resistance of the transformer. It also reduces the transformer’s ability to withstand the mechanical and electrical stresses that occur in operation.

Over time this will result in outages and/or the necessary down rating of the transformer and ultimately could result in complete failure.

“Moisture will decrease dielectric strength, accelerate cellulose aging and cause the emission of gaseous bubbles at high temperatures”.

Where does Moisture come from?

- Moisture accumulates in the transformer over the years of its operation.

- There are typically three sources of moisture for a transformer

1) New transformers are meant to carry some moisture in the paper insulation.

2) From the atmosphere via the conservator and through the breather in free-breathing transformers.

3) Moisture is created due to the breakdown of the solid insulation during normal loading and operating conditions.

Moisture in oil reduces the insulating ability (BDV) of the oil

ReadMore>>

- With sudden high loads, water can evolve out of the conductor surfaces and the vapour bubbles can rise to the contacts and result in a failure.

- During sudden cooler or low-load periods, the relative saturation of oil will increase greatly reducing the dielectric strength of the oil.

<<ReadLess

Moisture in paper causes the following destructive effects

ReadMore>>

- Sludge settles on windings, causing reduced efficiency on transformer cooling. Acids increase the rate of decay, which forms more acid, sludge, and moisture at a faster rate.

- Expansion of the paper insulation, altering the mechanical pressure of the transformer clamping system.

- Decrease in Dielectric Breakdown strength of the oil.

<<ReadLess

DryTrans is a brand of moisture management systems under the AVACO banner. It is a result of two decades of industry experience. AVACO Solutions is based out of SHARJAH, U.A.E. DryTrans is designed and manufactured in the United Arab Emirates.

Downloads

06-573-8439

+971 6-573 8597

Contact Address

Sharjah Airport Free Zone SAIF Zone Q3 – 190 P.O.Box: 514585 Sharjah, United Arab Emirates

support@drytrans.com