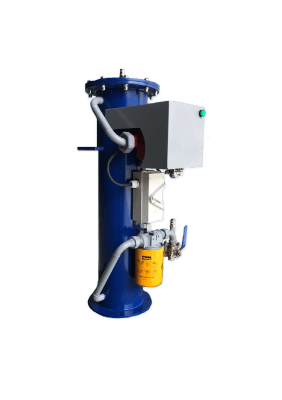

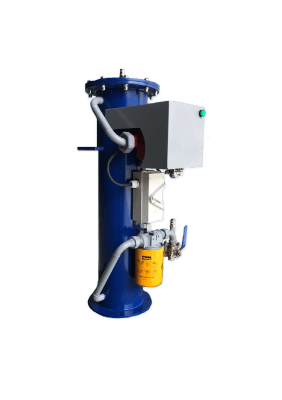

Model: MMS90

State of the art SMART moisture manager with integrated Touchscreen HMI interface and SCADA compatible.

"We believe in a healthy, reliable and well-maintained network. Optimize the performance of your transformer, extend its life, protect the environment, and create a safe and efficient workplace".

Integral Oil Leak Trip

Innovative & Effective

Leak Proof Design

Smart Systems Integration

Increased Machine Reliability

High Efficiency Pump

Interlocked Safety

Efficient Adsorbent Media

Easy Install

HMI Interface

Discover

Molecular Sieve 3A Zeolite beads are used for adsorbing the moisture from the oil. According to the beads manufacturer the beads will not remove any gas molecules from the oil, thus not affecting the DGA results. This allows the unit to be specific for moisture removal only.

The unit is fitted with a media replacement valve at the bottom of the unit, which uses gravity to remove the media from the unit. This procedure saves time and energy for site personnel and makes the media replacement very easy and simple

When the media needs to be replaced, an oil emptying procedure is initiated to transfer most of the oil from unit cylinder back to the transformer prior to replacing the media. This procedure reduces the oil wastage and handling, thereby making the media replacement very easy and environmentally friendly.

The TR20 / TR50 have been designed with two spare installation points for moisture sensors. These moisture sensors with local display, allow the user to view the moisture data at the inlet and the outlet as needed. These sensors are optional and installed on request. On the MMS90 two moisture sensors are included as part of standard supply

The MMS90 is outfitted with a clearly visible touch screen interface allowing the user to interact with the unit and perform all necessary functions as well as view stored data points.

The units are equipped with 3 speed settings on the motor.

The TR20 / TR50 are equipped with Flow Indicators as part of standard supply and the MMS90 is equipped with a Flow Meter as standard. The TR20 / TR50 can be equipped with a flow meter as an optional item.

The cabinet has been designed for outdoor installations to protect the filtration unit housed within. The cabinet has been factory and site tested to meet rugged and harsh environments and extreme temperatures.

The unit is equipped with an internal oil sump with a trip function that will collect the oil leaking in the unit. The leaking oil will collect in the sump located in the base of the unit and will trip the system when a preset level is reached, operate and close the solenoid valves at the transformer and isolate the transformer.

The unit comes equipped with a standard particulate filter to filter any carbon or other suspended particulates in the oil.

2900 RPM GRUNDFOS motor with an adjustable flow rate between 100 – 500 LPH

The unit has two oil sampling points (inlet and outlet)

A Suite of Moisture Management systems for all rating transformers

DryTrans is doing their bit in

protecting the environment

- Reducing the number of oil changes during maintenance schedules

- Reducing the overall Carbon Footprint on the environment

- Helping to protect the environment and provide additional benefits such as reduced costs and demonstrate positive Corporate Social Responsibility

- Extremely eco-friendly and doesn’t harm the environment with its disposal of media.

DryTrans is a brand of moisture management systems under the AVACO banner. It is a result of two decades of industry experience. AVACO Solutions is based out of SHARJAH, U.A.E. DryTrans is designed and manufactured in the United Arab Emirates.

Downloads

06-573-8439

+971 6-573 8597

Contact Address

Sharjah Airport Free Zone SAIF Zone Q3 – 190 P.O.Box: 514585 Sharjah, United Arab Emirates

support@drytrans.com